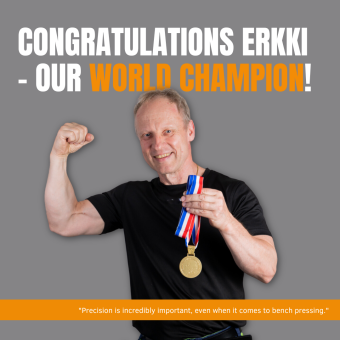

Our very own Erkki Rajala has done it again. In July, he surpassed his last EC gold and beat his own world record from last year during EC bench press in Mérignac, France.

Lue lisää

We have the capability to produce advanced mechanical components entirely in-house, from inception to completion, within our very own factory.

Lue lisää

Until recently, we were satisfied with being nearly flawless. But why settle for proximity when you can achieve greatness?

Lue lisää

We are used to solving our customers' engineering problems. In this case, it took a few extraordinary solutions before we could go on with the process.

Lue lisää

While Finland may not be known for its sunny summers, at Keymet, the sun is always shining thanks to our happy colleagues and their magnificent problem-solving skills!

Lue lisää

Our commitment to precision and delivering uncompromised quality is unwavering and evident in every single metal part. That's why we have the entire manufacturing chain in-house, so we can ensure that every detail is just right.

Lue lisää

We recently invested in a new Waterjet. With multi-head cutting the process will be up to three times faster.

Lue lisää

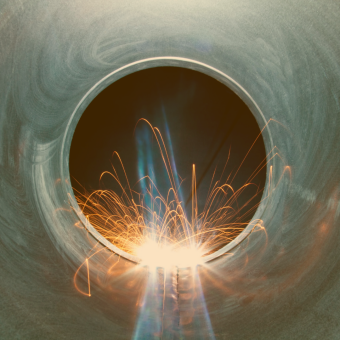

The best part of my job is that I always feel appreciated, says Jonas Holmstedt, team leader of the welders at Keymet. Every day is different and we are challenged on a daily basis in our work.

Lue lisää

At Keymet, precision is not just a buzzword - it's a way of working.

Lue lisää

When we asked our Key Account Manager Kristoffer Jåfs what the best part of his job is, he didn't hesitate before answering: the customer contact.

Lue lisää

When our customers need parts for their projects that must be able to withstand a long life under water, it requires extraordinary materials. These shining parts are made of forged acid-resistant material - a unique material that you won't find in just any product specification.

Lue lisää

When we started working with the aerospace industry, we spent a great deal of time researching what type of machine would meet our precise standards for large part machining. The research paid off when we found the 5 axis Haas.

Lue lisää

Advanced planning and production of metal parts for the manufacturing industry are our expertise.

Lue lisää

This is the story about how we solved an unsolvable problem through excellent machining, top-notch engineering skills, and world-class CNC milling.

Lue lisää

In the first week of January, a part of our team started a challenge.

“Who can raise their personal best in bench press the most before Christmas”?

Lue lisää

In the end of February we were paid a visit by the local newspaper, who made a article about our CEO Mikael Lillvik. We got to read about his career, how he ended up applying for the position at Keymet and a moment in his career he will never forget.

Lue lisää

With great power comes great responsibility, as Roosevelt once said.

Taking part in this competition held amongst the many successful companies in our region has been fun. The part you get to see of our team here on social media, is just a drop in the ocean of everything we do together.

Lue lisää

It is with great excitement that we announce the appointment of Mikael Lillvik as the new CEO of Key

It is with great excitement that we announce the appointment of Mikael Lillvik as the new CEO of Keymet. Mikael brings a wealth of experience and expertise to the role, having spent 30 years holding leadership positions at several different companies.

Lue lisää

Working in Finland, companies generally provide you with free "health-tickets". At Keymet we use an extended version named ePassi that provides you with different types of excersice or health-beneficial services such as training at the gym, swimming indoors or getting massages. In addition, it can also be used for cultural events

Lue lisää

A small but great part of our production chain, let us introduce our fully automatic turning machine

It's effortless and beautiful, but this level of automation would never be possible without a machine operator aiming for absolute perfect results when programming the revolver turner.

Lue lisää

It has been an exciting new start to this autumn with us facilitating the Jakobstads Mekano crew. We enjoy their humor on the coffee breaks as well as their expertise in advanced welding in our production hall.

Lue lisää

Efficiency is his middle name, and he has no problem taking on responsibilities. Meet Keymet’s eager beaver, Ram Bastola.

Lue lisää

We were invited to the #EHABTribeSummit2022 in Stockholm, hosted by entrepreneurs Saeid Esmaeilzadeh and Mouna Esmaeilzadeh, founders of Esmaeilzadeh Holding.

Lue lisää

Expertise in both sheet metal and machining technology gives us the opportunity to house the whole manufacturing chain in-house. We manufacture advanced mechanical components from start to finish in our own factory.

Lue lisää

Is Mats Holländer 26 years or has he been working at Keymet for 26 years? It’s a tricky question, we know, but the answer is that he is one of our long-term employees.

Lue lisää

Since we got our multipallet milling machine, Doosan 5000 RPS, we have increased production time on many of our projects.

Lue lisää

Wie geht’s Viktor?

Would you have guessed that as Viktor is navigating the CNC turning machine, he is in fact also listening to German speaking podcasts?

Lue lisää

The process of powder coating starts with applying a layer of dry powder on to the metal parts with an electrostatic paint sprayer, either by hand or with a robot.

Lue lisää

Are you used to working on airplanes? Wondering what that has to do with us?

Well, we provide airplane manufacturers with cages for WIFI-receivers.

Lue lisää

Producing mechanical components for the medical industry demands high quality control. Nothing short of perfection is acceptable.

Lue lisää

A little color never hurt nobody.

And it’s definitely not hurting our metal components that are both processed and painted in our own factory. Niklas Noon is working the painting station and has done so for a few years.

Lue lisää

For Linus, it’s always summer at Keymet.The plan was to stay over the summer, but Linus plans changed and now he finds himself still working at Keymet.

Lue lisää

Ludvig Björkskog is studying at his second year at Optima. His major field of study is metalwork, and he is particularly interested in improving his skills on the CNC-milling machine.

Young eager students fill our production hall a few times a year. We are cooperating closely with the vocational school Optima in Pietarsaari and gladly provide their students with internships.

Lue lisää

This is the end station for sheet metal components before they are carefully packed and shipped to the customer.

Lue lisää

We are looking for someone who is passionate about being a driving force in Keymet's continued success!

Lue lisää

We produce advanced mechanical components from start to finish in our manufacturing plant.

Lue lisää

Expertise in both sheet metal and machining technology gives us the opportunity to house the whole manufacturing chain in-house. We manufacture advanced mechanical components from start to finish in our own factory.

Lue lisää

Have a question? Jimmy surely knows the answer.

As our production manager Jimmy Eklund is all ears and simultaneously the well of knowledge.

Lue lisää

From sheet metal to a finished processed product, both painted and marked under the same roof.

Lue lisää

We cater to the electronics industry by manufacturing various numbers of mechanical components. Fastening plates, non-standardized screws, cases, lids, bottoms, and panels are examples of components that we produced.

Lue lisää

We offer series production on a large scale. And still, it’s all in the details.

Lue lisää

You’ve probably heard that we manufacture components from start to finish under one roof. This is the end station for sheet metal components before they are carefully packed and shipped to the customer.

Lue lisää

Keeping track of the entire production chain with the customers’ requirements in mind, is Jenni’s key responsibility.

Lue lisää

Keymetin laatujärjestelmä on uudelleenarvioitu kolmeksi vuodeksi. Yrityksemme järjestelmä uudistettiin moitteettomasti ilman poikkeamia.

Lue lisää

At Keymet we find environmental issues important. We want to take responsibility and have control over the company´s environmental impact.

Lue lisää

Keymet is proud to announce about the collaboration with Omnisys and NASA's project GUSTO (Galactic/extragalactic Ultra long duration balloon Spectroscopic Stratospheric THz Observatory). Keymet have been given the honourable mission of producing mechanics for the GUSTO- project.

Lue lisää

Marisol Zamora, Keymetin lentokoneteollisuuden projektipäällikkö, tapasi Airbus A350 First Officer Christian Krohnin. Keymet valmistaa lentokoneiden ohjaamoissa tarvittavia erikoistuotteita. Tapaamisella halusimme laajentaa tietämystämme siitä miten tuotteita käytetään ja mitä uutta voisimme valmistaa tulevaisuudessa. Alla artikkeli englanniksi.

Lue lisää